Rotary gas meters are positive displacement meters for measuring industrial and commercial gas flows. This style of meter is known for its high accuracy across a wide range of flows in a compact sized design. They typically use intermeshing, figure-8-shaped impellers to create a seal, trapping and moving a precise volume of gas for each rotation to accurately track total volume.

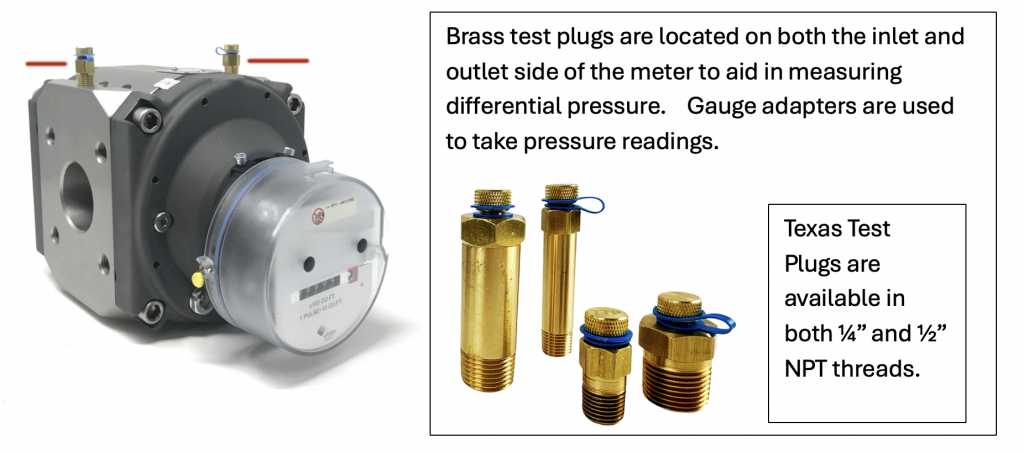

Rotary gas meters have test ports on the inlet and outlet side. This provides a way to measure the differential pressure across the meter’s impellers. This differential pressure test checks the meter’s mechanical health by monitoring internal friction. A significant increase in the pressure drop can indicate excessive wear or other performance issues. These test ports allow for periodic monitoring and establishing a baseline for meter performance.

Texas Test Plugs are widely used on rotary gas meters due to their proven long-term performance, low cast, and off-the-shelf availability. We work with OEM’s to provide, reliable, scheduled deliveries.

Purpose of the Test Ports

Differential Pressure Monitoring: The primary purpose of these ports is to allow for differential pressure (DP) testing.

Health Check: Measuring the DP across the meter provides insight into the internal resistance of the meter’s components, indicating their condition.

Baseline Data: Initial differential pressure readings are taken at various flow rates to establish a baseline curve for the meter. This curve shows the expected pressure drop at different flow rates when the meter is new.

Performance Tracking: Future tests compare current DP readings to the baseline curve to identify changes in performance.

Early Warning for Issues: A significant increase in the differential pressure (often considered a 50% rise from the baseline) suggests increased internal friction, which can lead to accuracy issues and a need for service.